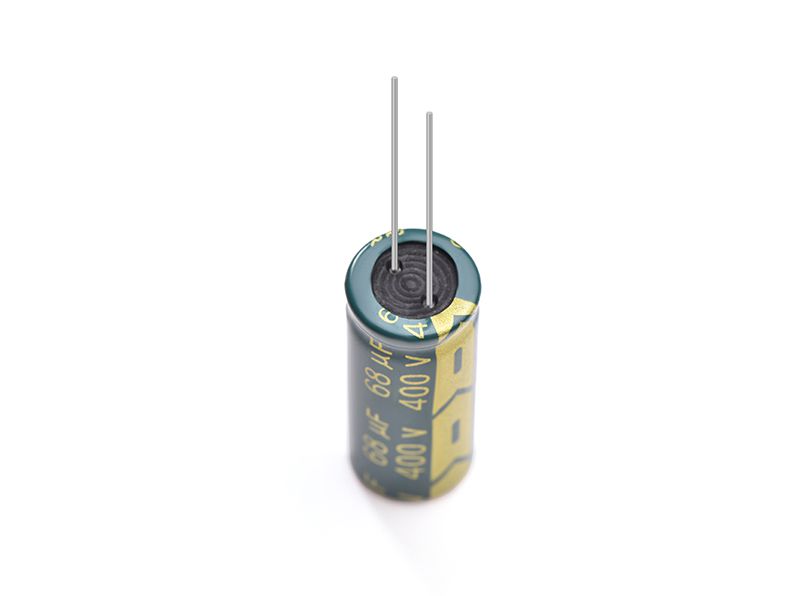

Electrolytic capacitor 68UF400V.

SHDR® Application Notes

Reverse voltage causes short circuit breakage of the capacitor or leakage of electrolyte. Where the polarity in a circuit sometimes reversed or unknown, a bi-polar capacitor should be used.

When you use aluminum electrolytic capacitors, remember the following:

1. Polarity

Regular aluminum electrolytic capacitors has polarity

Reverse voltage causes short circuit breakage of the capacitor or leakage of electrolyte. Where the polarity in a circuit sometimes reversed or unknown, a bi-polar capacitor should be used.

2. Overvoltage

Do not apply overvoltage continuously.

When overvoltage is applied to the capacitor, leakage current increase drastically.

Applied working voltage to capacitors should not exceed the rated working voltage of capacitor.

3. Operating temperature and life

Do not use the capacitor over the max operating temperature.

Life time of the capacitor depends on the temperature.

Generally, life time is doubled by decreasing each temperature 10℃

Use temperature as low as possible.

4. Vent

It is recommended at least 3mm of space around the vent.

If such space is not provided, the vent will not operate completely.

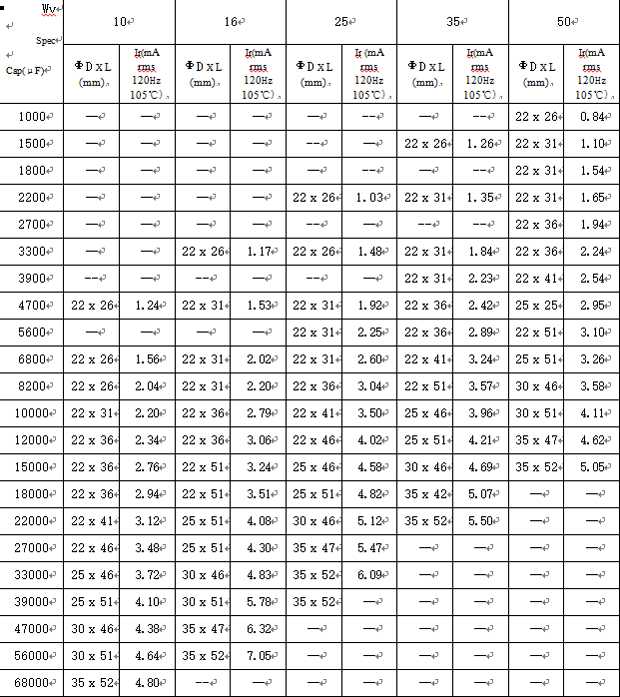

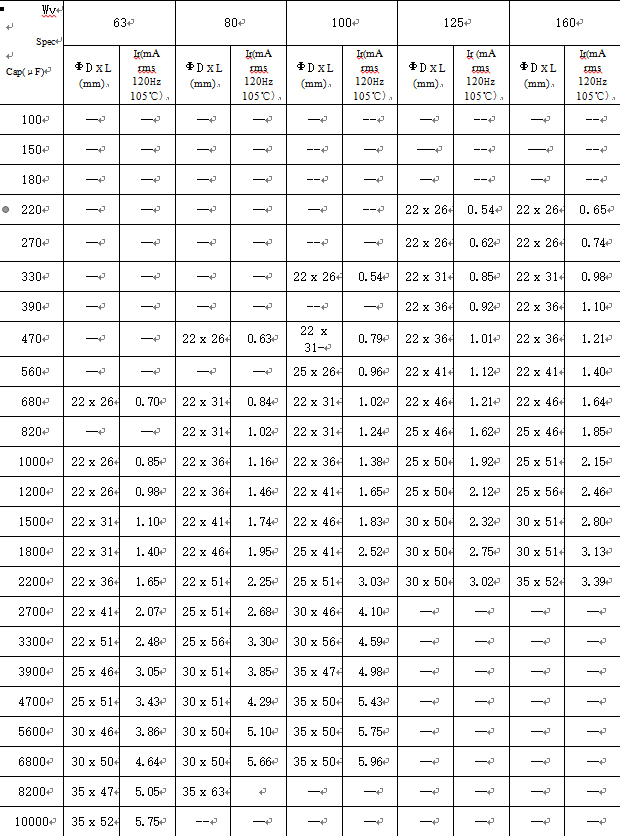

5. Ripple current

Do not apply a ripple current exceeding the rated maximum ripple current.

Applying too much ripple current to the capacitor causes great heat generation, invites deterioration of properties of causes breakage.

Please consult factory if ripple current exceeds the specified limit.

6. Charge and discharging

Frequent and quick charge/discharge generates heat inside the capacitor, causing increase of leakage current, decrease of capacitor, or breakage occasionally.

Consult us for assistance in this application.

7. Storage

When the capacitor is stored for a long time without applying voltage, leakage current tends to increase.

This returns to normal by applying the rated voltage to the capacitor before use.

It is recommended to apply D.C. working voltage to the capacitor for 30 minutes through 1kΩ of protective series resistor, if it is stored for more than 6 mouths.

The capacitor should be stored at a normal temperature and humidity.

8. Soldering

Improper soldering may shrink or break the insulating sleeve add/or damage the internal element as terminals and Lead wires conduct heat into the capacitor.

Avoid too high a soldering temperature and/or too long a soldering time.

9. Mechanical stress on the lead wire and the terminal

Do not apply excessive force to the lead wire and the terminal.

Do not move the capacitor after soldering to the PC board, not carry the PC board by picking up the capacitor. For their strength, refer to JIS C-5141 and C-5102.

10. Cleaning of boards after soldering

If the capacitor is cleaned in halogenated solvent for organic removing solder flux solvent, the solvent may penetrate into inside of capacitor, and may generate corrosion.

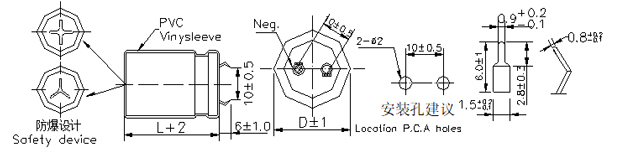

11. Sleeve material

The standard sleeve material is polyvinyl-chloride.

If exposed to xylene, toluene, etc, and then subjected to high heat, the sleeve may crack. This sleeve is not insulating material.

12. Micon's Products meet or exceed quality standards specified by JIS-C5141W and with the reliability requirements refer to JIS-C-5102.

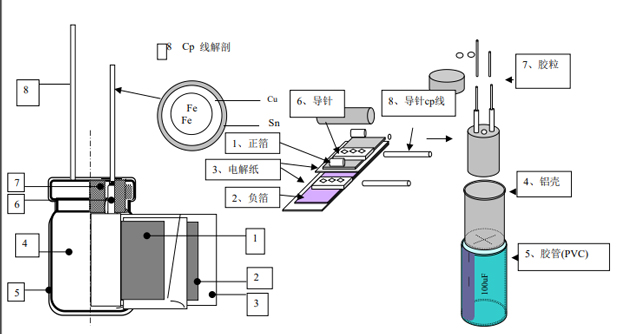

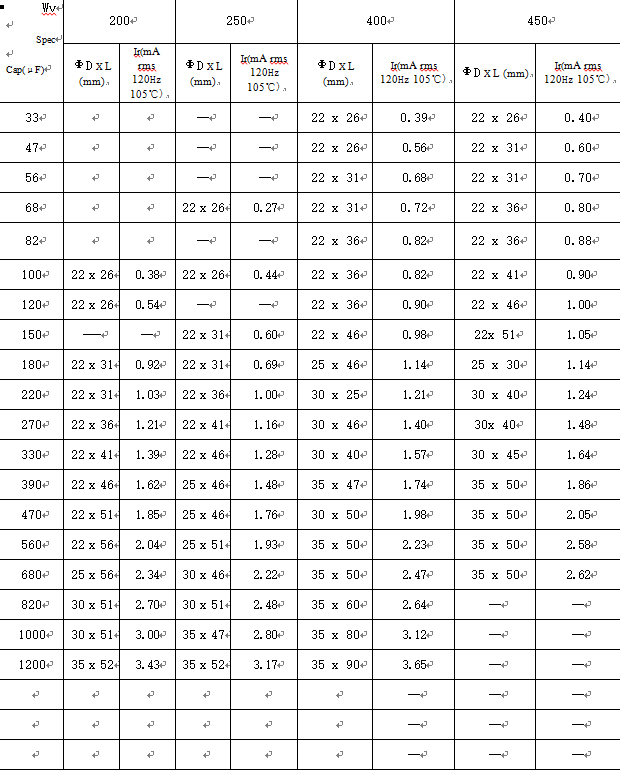

Capacitor structure detail diagram

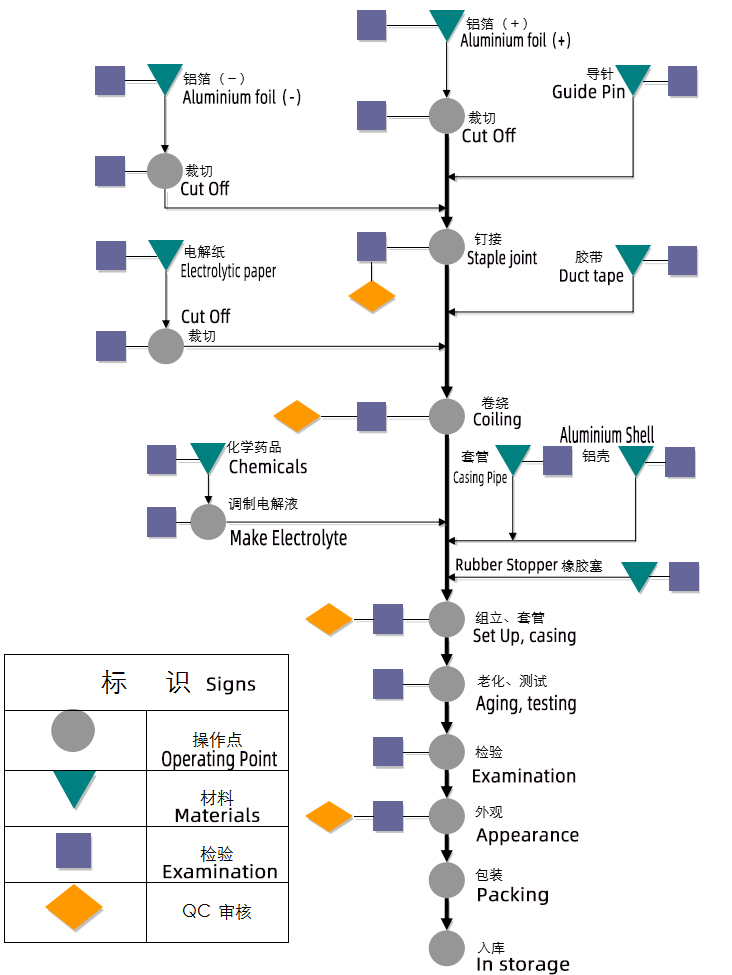

Capacitive process flow

For other custom capacitors you can contact us and we will give you a good price.

Product Picture

Copyright © Guangzhou Shenghe Electronic Technology Co., Ltd. All Rights Reserved Sitemap | Powered by